The global manufacturing industry is presently undergoing a transformational phase. A decade ago, product development used to be a discipline that required painstaking hours of designing, blueprinting and working collaboratively with people. Today, disruptive technology is facilitating faster turn-around times and fostering a culture of innovation.

In recent times, major industrial sectors have visibly become more involved with how technology impacts the overall workflow. However, unlike other functions, manufacturing has seemingly struggled to keep up with the pace of this changing trend. Against this backdrop of transition, following are some of the impactful technology trends that are set to shape the industry going forward:

Virtual-reality for advanced simulation

3D simulation, which is already being employed at the engineering level is not a flight of fancy for the manufacturing sector. The transition, however, is its involvement in full-fledged plant operations. Advanced 3D simulations will involve real-time data to replicate the physical world in a virtual model. The operators will have the edge to assess and optimize the instrument settings in a virtual setup before the actual physical changeover. This will curb machine set-up times, thereby augmenting overall production efficiency and accuracy.

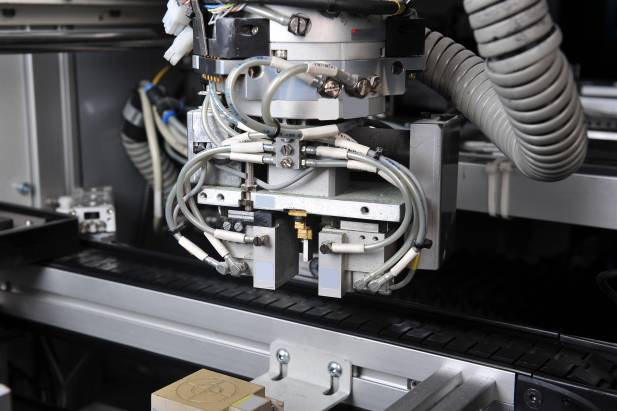

Automation of work through robotics

It is estimated that by 2018, almost 1.3 million new industrial robots will be working in factories globally. Key industrial hubs like China are already making massive investments in advanced robotics to promote enhanced automation. Moving forward from ‘limited intelligence’, robots now are increasingly becoming more perceptive and versatile.

Involvement of advanced predictive analysis

Realizing that holistic sustainability depends heavily on mastering machine language algorithms, global manufacturing processes are gradually imbibing predictive analysis as a best practice. From preventive maintenance, which predicts equipment malfunction to proper process control and inventory management, advanced predictive analysis is set to change the face of manufacturing in the near future.

Mainstream adoption of industrial 3D printing

Additive manufacturing or 3D printing has already transformed the way the world looks at product customization. It has not only allowed more flexibility to custom designing but also expanded the R&D horizon for various manufacturing processes. By blurring the lines between prototype and product, 3D printing is expected to bring about a paradigm shift and create precisely identical parts of a specific product, thereby reducing costs. Growing at a CAGR of 25%, the market is slated to reach a whopping USD 20.4 billion by 2019 and act as a major driving force for the global manufacturing industry.