As e-commerce continues to grow exponentially in the post-pandemic times we live in, the need for smart and sustainable packaging has become more acute than ever. Both brands and consumers are actively seeking ways to reduce their environmental footprint and make eco-friendly transitions to more sustainable packaging methods. Maximizing the use of recyclable and biodegradable materials various innovative alternatives have cropped up. From using PET resin and polyester fiber and pulp to even mushroom roots, here are a few sustainable packaging innovations that are expected to stick this year:

Eco-friendly inks

Have you ever thought of what goes into the inks used for printing across packaging and how that breaks down in the environment? Small prints are often dangerously toxic. These are traditional petroleum-based inks containing volatile organic compounds (VOCs) that are harmful to the environment.

Alternative biodegradable inks are not only easier to de-ink during the recycling process, but they also have the same high-quality color vibrancy and aesthetic appeal. With the eco-friendly ink market growing at over 4.5% yearly, some of the up-and-coming alternative inks include:

- Biodegradable inks: Using natural vegetable oils like soy, rapeseed, and sunseed, biodegradable inks are generally more cost-effective and produce vivid colors. Less ink is utilized when printing and it is a non-toxic solution that doesn’t emit pollutant smells. For instance, Green Tees, a UK-based golfing product, utilizes packaging made of biodegradable bamboo and is printed using biodegradable ink.

Sustainable bamboo golf tees

Biodegradable ink on recycled packaging

- Water-based/Flexographic inks: These inks eliminate the use of petroleum-based chemicals and solvents that increase VOC levels and consume more energy. These are generally less environmentally dangerous. Aside from packaging, this ink type is making its mark in the fashion industry. Milan-based brand MSGM announced the usage of water-based inks in their latest ‘Fantastic Green’ collection.

- Vegetable/Soy inks: Typically either derived from organic compounds like soybeans or corn oil, vegetable-based inks are designed to print in a manner that reduces the release of VOCs. The utilization of natural components in these inks makes recycling easier as they break down faster than traditional inks. Ritual – a vitamin supplements company, recently announced that starting April 2021 they are using plant-based ink and even switching their vitamin mail packaging to material exclusively made from recycled fibers and newsprint.

- UV and EB curable inks: Inks curable by UV (Ultraviolet) or EB (Electronic beam) processes are printed by polymerization – a network of polymers generated that quickly dries as ink – upon exposure. This means they don’t emit any VOCs and have no solvents. UV inks are cleaner, require less wastage, and reduce energy consumption by as much as 50%.

- Air Inks: Inks made out of air pollution, air ink is the first of its kind. They are safe, high-quality, refillable, and water-resistant. Largely used in markers and for art and design, packaging can soon incorporate its usage.

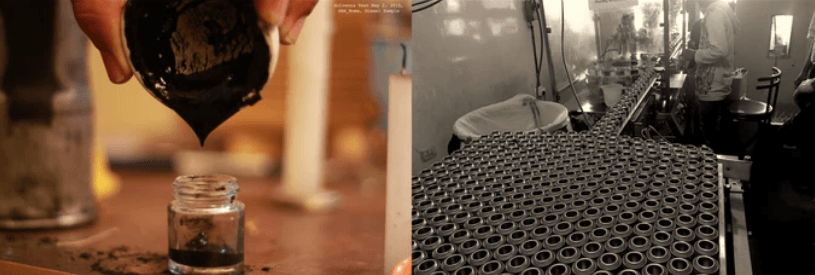

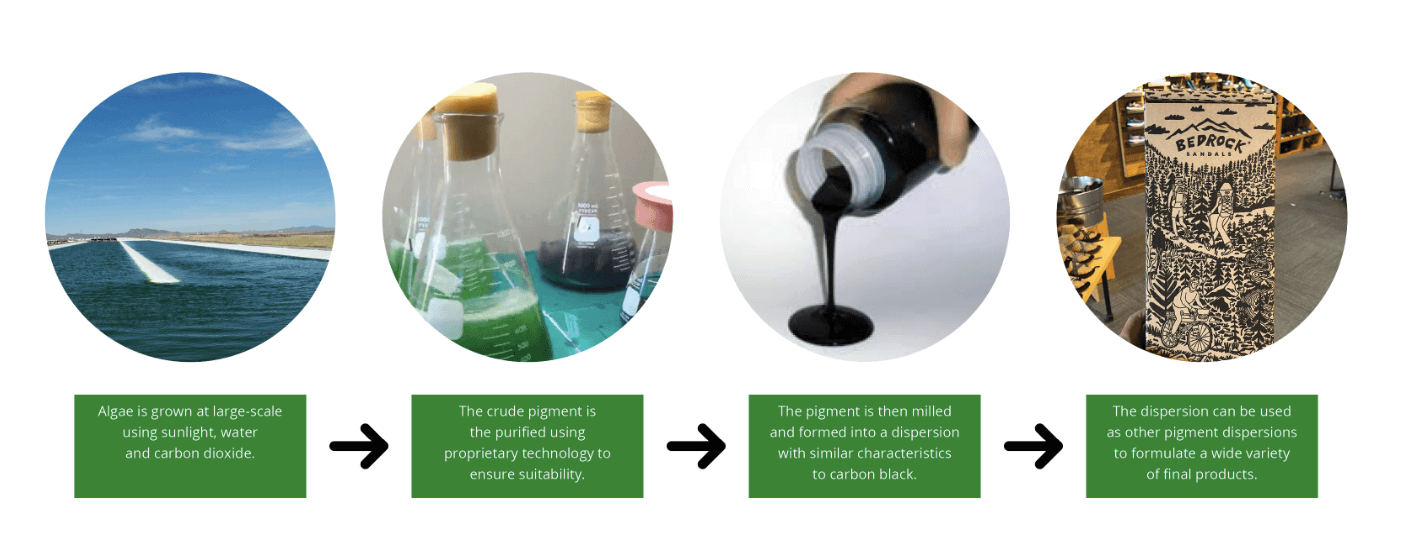

- Algae Ink: A niche alternative to water-based or vegetable inks, algae ink is another alternative for packaging or as domestic printer ink. In this case, algae is grown on a large scale and then the pigment is purified to produce the ink.

Plant-based packaging

Plant-based packaging options have seen massive growth. With materials made of biological sources. These range from seaweed and mushrooms to corn and food waste. However, the right packaging option depends on the product being packaged or shipped. For instance, for food, the material in question (bioplastics is a good alternative) must protect the product without affecting its flavor. Bulkier goods require a durable plant base like mushroom and cornstarch.

Usually, byproducts of industries like agriculture, help minimize supply chain waste. For instance, compressed plant fibers like coconut and mushroom filaments can be utilized in e-commerce businesses as biodegradable packaging alternatives. As an alternative to plastic poly mailers, compostable mailers are made from corn starch.

This bio-based polymer utilizes only 0.05% of the annual global corn crop, thus serving as an incredibly low impact design. Ecovative Design’s mushroom-based packaging called MycoComposite has been adopted by IKEA in its initiative to reduce wastage. Grown in a controlled environment, the packaging can grow around a mold, which then exactly fits the product.

Mushroom packaging by Ecovative designs

IKEA’s usage of MyoComposite

Large global brands like Coca-Cola, Nike, Procter & Gamble, Ford Motors, and Heinz came together in collaboration in 2012 for a Plant PET Technology Collaborative (PTC) that focuses on integrating the use of 100% plant-based fibers and PET materials in their products. Today, large firms across the globe have adopted plant-based packaging for their products:

- Plantic, a plant-based packaging manufacturer looks to extend the shelf life of non-durable products.

- Newspaper giant, The Guardian, aims to start using a malleable film made of potato starch – Bioplast 300, to wrap newspapers.

- Danone recently partnered with Avantium, a biotech company, to produce bottles made from renewable materials of bio-based plastic which won’t threaten food resources.

- Kelloggs, Pepsico, and Mondelez International plan to equip consumers with adequate recycling information and develop 100% recyclable, reusable, and potentially compostable packaging materials by 2025.

Edible Packaging

Made of biodegradable, natural, and plant-based components, edible packaging can be consumed to be eaten- eliminating the need for waste management. Comprising zero-waste packaging materials, it is an ideal option for retailers selling food and beverages- even serving as a great addition to already delicious edible offerings. A few examples include:

- A seaweed-based container- made of biodegradable seaweed and calcium chloride, the Ooho edible water bubble manufactured by Notpla is an excellent alternative to plastic containers.

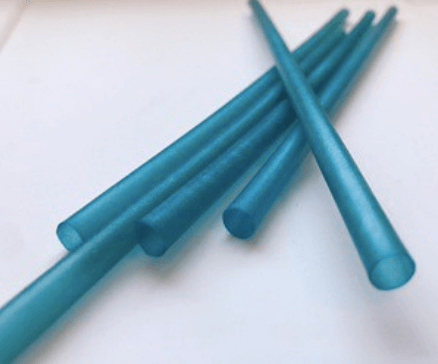

- Loliware manufactures edible cups, straws and other containers with materials like seaweed and algae extract, even offering flavors like yogurt, grapefruit, and cherry.

Source: C&ENNews

- MonoSol has come up with water-soluble films made of Polyvinyl Alcohol (PVOH) that entirely dissolve as soon as they come in contact with water, consumed by bacterial microorganisms after its use. Neither persisting in the environment nor contaminating the recycling stream, it is uniquely safe for everyday sustainable use.

- Bakeys has manufactured biodegradable and vegan-friendly spoons made from rice, sorghum, and wheat. Sorghum can grow in arid environments and depleted soil and is also known for its resilient qualities. These spoons don’t get soggy easily either.

- Evoware makes edible and disposable sachets made of seaweed- serving the same function as plastic packaging, but with the added advantage of dissolution in warm water.

Plant your package!

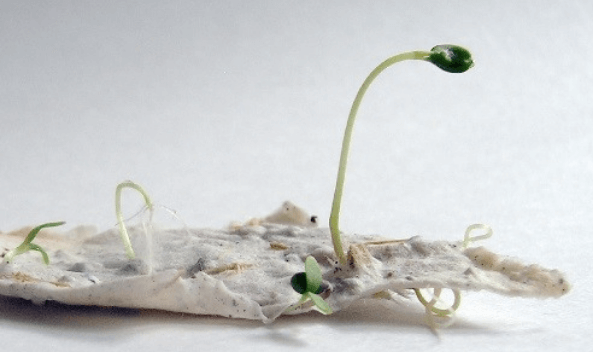

Ever heard of planting your packaging? Plantable packaging does exactly that! Packages consist of materials that can be planted, having seeds embedded in them that customers can go on to plant when they’re done using the packaging. This packaging is great for lightweight and small items like cosmetics and jewelry. They can also be used as product wraps or fillers. For instance, Pangea Organics collaborated with Seeds of Change and UFP technologies to create the first 100% compostable and plantable packaging.

Manufactured aiming towards zero waste, once the product has been used, consumers soak the product’s fiber box that contains seeds, plant it in the soil to eventually find it sprouting medicinal herbs. Bloom Chocolates are another example of products using plantable packaging. Their biodegradable chocolate packages contain seeds of the flavor of chocolate like mint, rose, etc., thus bringing their product to a full circle with one more plant.

Pangea Organics bar soap

Planting your packaging

Lightweight Packaging

Reducing the overall amount of material used while packaging alone has become a fast incorporated sustainable strategy for brands. This not only decreases greenhouse gases used in product distribution, but lighter goods also weigh less which saves fuel while transporting and saves costs. Reducing shipment sizes includes using fewer filler materials and purchasing smaller packaging supplies.

Playing around with size and positioning fits products into smaller packages. For instance, disassembling furniture parts while shipment and selling are some of the basic examples of reducing packaging for a large product. One can explore ways of positioning, folding, and bundling products to save space and snugly package them in smaller boxes.

Biodegradable and compostable alternatives for plastic

Substituting plastic packaging with biodegradable alternatives that can be composted is the way forward. These packages are often made from plant-based polymers which can break down in the composting process. The quality and materials determine their breakdown in a commercial or domestic compost facility within 90-180 days. A few examples of compostable wrapping alternatives include:

- BOSS Food uses compostable wrappers for its vegan superfood bars. Made by TIPA with its proprietary bio-based blend, it has all the properties of plastic, with the added certification for industrial and home composting. TIPA engages in conducting shelf-life tests that compare product and packaging shelf-life to conventional packaging processes.

- Celestial Tea’s tea bags are compostable with their outer boxes made with 100% recycled paperboard. They don’t use individual wrappers, strings, or staples for their teabags, saving 3.5 million pounds of landfill waste in one year alone.

- Kellogg’s is working towards replacing the plastic cereal pouches in its European products with recyclable materials by the end of this year with a goal of 100% sustainable packaging by 2025.

- Walmart too is phasing out single-use plastic bags and adding recycling labels for consumer benefit aiming to reach 100% recyclability by 2025.

- L’Oreal for its packaging bottles is using biodegradable and compostable paper that resists water.

Advanced packaging design

Designing a package suitable for reuse and recycling can be done by keeping the post-use purpose in mind. For instance, H&M designed a shopping bag that, once used, can be used as a clothes hanger. Made from less material than the traditional H&M bag, the paper used is 80% recycled. Targeting an age group between 18 and 35, their young consumer base is conscious of their environmental footprint and these initiatives further encourage brand loyalty.

Vienna-based jewelry studio Sheyn offers simple and elegant designs utilizing 3D printing for their products. This technology renders their product entirely sustainable. Further, for their packaging, their eco-mailer box uses 80% recycled material and an online editor to incorporate their unique design into packaging with a memorable unboxing experience. This strategy further serves to engage consumers throughout their product purchase experience.

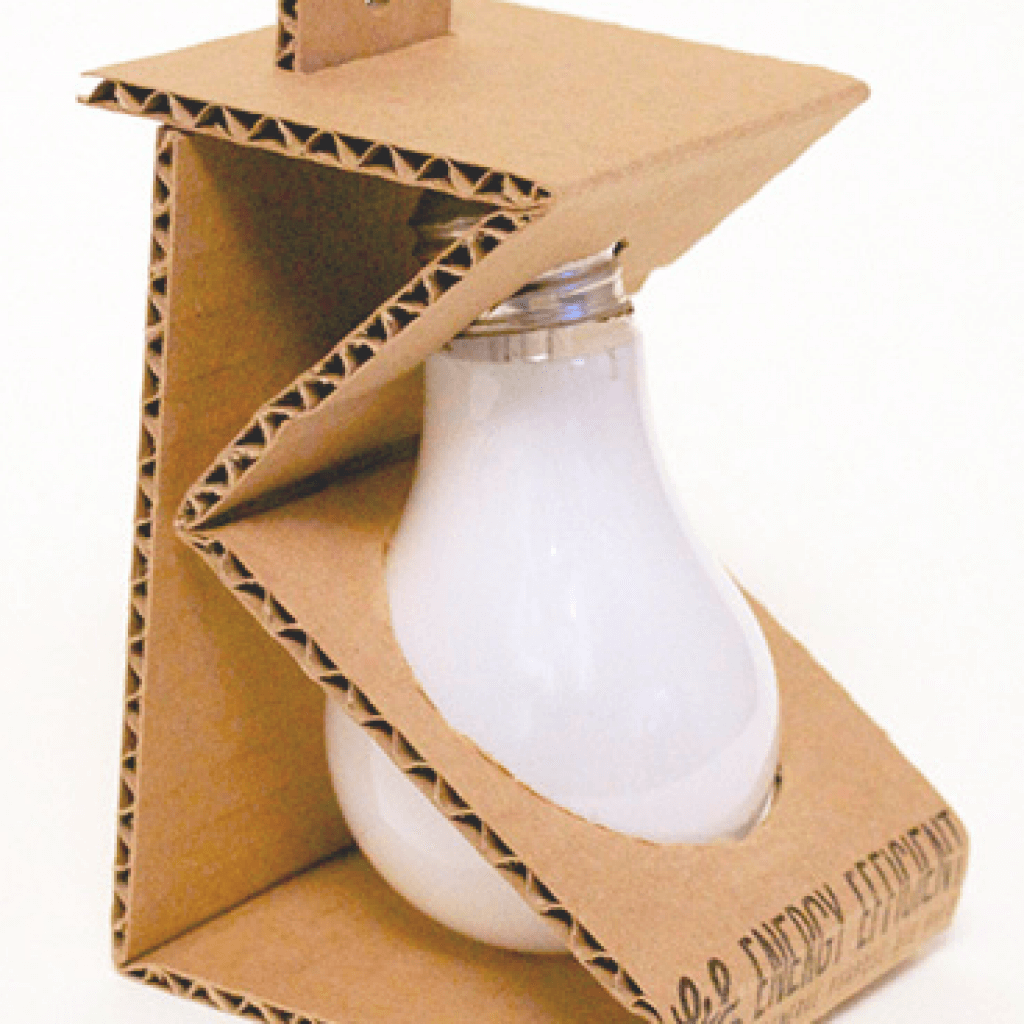

Utilizing paper, pulp, or cardboard and other alternatives for sustainable packaging also open the doors to a variety of innovative design that not only optimizes the packaging material used but also attracts more customers. For instance, this shoe and bulb packaging not only looks unique but is also lightweight and optimizes on space and material. Packaging design is a crucial aspect of packaging that can make or break product purchases, quite literally.

Sustainable packaging innovations have greatly expanded giving rise to some wonderful out-of-the-box alternatives. Adopting sustainable packaging innovations helps resolve multiple issues. From tackling rapidly changing climate, air, water, and soil pollution to rising temperatures, and species extinctions. Savvy brands are already employing sustainable packaging practices as it not only boosts their brand’s environmental impact but also helps increase corporate social responsibility and support communities by creating gainful employment and resource conservation.

Netscribes’ innovation research and market intelligence solutions allows organizations to stay on top of emerging trends for a competitive advantage. To know how you can best leverage this winning packaging trend or know what industry front runners are doing to capitalize this space, contact us.